The most accurate predictions of hydrate formation conditions are made using commercial phase equilibria computer programs.

The process is analogous to extractive distillation with a high-boiling liquid. Although inferior to water or ethylene glycol, both MIPK and MIBK would probably be acceptable for reversing the natural volatility of the system.Įxtractive Distillation by Salt Effects A second method of modifying the liquid-phase behavior (and thus the relative volatility) of a mixture in order to effect a separation is by the addition of a nonvolatile, soluble, ionic salt.

Of these, water (the solvent used industrially) clearly has the largest effect on the activity coefficients, followed by ethylene glycol. Other members of the homologous series, along with water and ethylene glycol, have acceptable boiling points (at least 30☌ higher than keys). Methylethylketone boils too low, as does ethanol, and also forms an azeotrope with methanol. Table 13-22 shows the boiling points and experimental or estimated infinite-dilution activity coefficients for several candidate solvents from the aforementioned groups.

Thus, after discounting halohydrocarbons for environmental reasons, the best solvents will probably come from alcohols, polyols, and water for recovering methanol in the bottoms and ketones for recovering acetone in the bottoms.

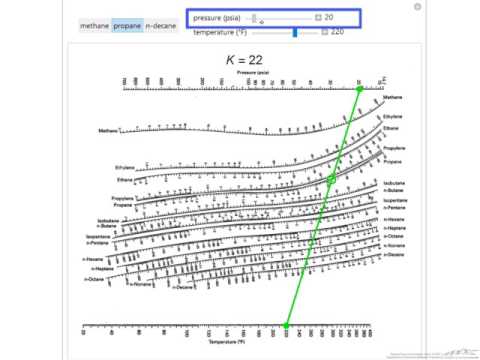

Depriester chart for methanol series#

The other qualitative indicators show that both homologous series (ketones and alcohols) look promising. Halohydro-carbons and ketones are expected to give positive deviations for methanol and either negative or no deviations for acetone.

Unfortunately, both ethers and hydrocarbons are expected to give positive deviations for both acetone and methanol, so should be discarded. For reversing the natural volatility, solvents should be chosen that are less polar than acetone, such as ethers, hydrocarbons, and aromatics. Turning to the Robbins Chart (Table 13-15), favorable groups are amines, alcohols, polyols, and water since these show expected positive deviations for acetone and zero or negative deviations for methanol. Tertiary ketones and alcohols (Table 13-21), solvents favored for the recovery of methanol in the bottoms would come from groups more polar than methanol, such as acids, water, and polyols.

0 kommentar(er)

0 kommentar(er)